Browse topics below to find what you want.

Support Library

Find datasheets, operation manuals, certifications, declarations, tech docs, diagrams, etc.

Product Registration

Register your product to establish ownership and expedite technical support.

String Calculator

Determine optimal series and parallel module configurations for your application.

Answers to FAQ’s

See the answers to the most frequently asked questions we have addressed over the years.

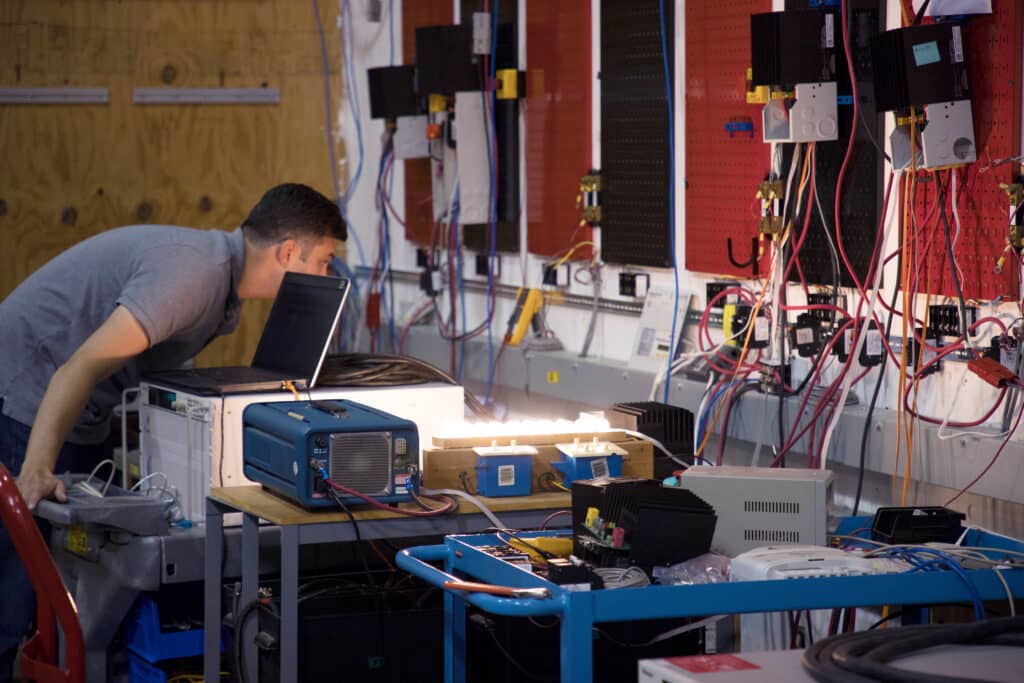

Morningstar’s Commitment To Technical Support

Over 90% of those surveyed rate Morningstar Technical Support as either “above average” or “really exceeding expectations.” In fact, they rate our Technical Support better than any other charge controller brand.

Unlike other companies that have outsourced their support, we have a US-based team of full-time professionals with over a half-century of combined renewable energy experience. Technical Support is all they do, and they do it very well. Take our customers’ word for it.

They’re dedicated to providing fast resolution on any issues, including product registrations, warranty claims, and access to datasheets, manuals, technical documents, firmware updates and other information. And “fast resolution” means something to them. With an average response time of less than four business hours they’re setting the standards for others to try and match.

Let them know how they can help you, especially if you can’t find the information you need in our Support Library and Answers to FAQs on this page.

Our customers’ comments speak for themselves

“Real people actually are focused on solving the problem, not just getting you off the phone”

“Far above average for almost any industry in responding to my inquiries about equipment acquisition, operation, and guides”

“The support is second to none in my experience, the response is timely which is important especially for off grid users”

“Morningstar is concerned regardless of the size of the project… response time is awesome and the team seems like down to earth type people”

Quick to answer emails and call back… Very professional, very fast response times,

very informative in trying to solve problems”

“They answer your emails… most companies just blow you off… Easy to contact and personal”

“Concise , knowledgeable, answers to specific questions, showing a complete understanding of the product, not usually found these days”

“Stick with it, Morningstar. We have seen other companies go way down in the support side due to outsourcing”

“Knowledgeable assistance … support ‘knows the product perfectly’”